V BAND CLAMPS

V BAND CLAMPS

Jupiter V Band Coupling / Clamps are used to join piping, tubing, various gas or liquid tracks, closures, separators, regulators, filters containers, Turbo chargers, Engine joints etc.

These are non-standard type of clamps. We have developed numerous designs as per customer’s specific application requirements. Various designs of latches viz. quick release latch, toggle latch are also available.

This clamp consist of T-Bolt, Nut, Trunion, and Band with V-shaped retainers spot welded to inner band which wedges the flanges together. The shape of the clamp, T-bolt size, No. of V-segments, retainer thickness, material of the components is determined on the basis of an application requirements.

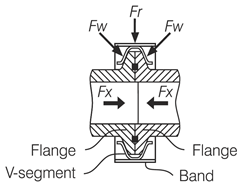

From the assembly shown in sketch it can be seen that the tapered inners of the V-segments are mounted over their respective matching tapers of the pair of flanges of the pipe joints.

The tangential pull created by applying torque by turn of nut causes uniform radial force Fr all around. This causes wedging action force Fw along the tapered area of the flange as its perpendicular. The Fw in turn has its resolved component force Fx along the axis of the flanges or pipes which effectively serves in firm and uniform fitting of the two flanges along their faces. The retainer applies a uniform closing force around the circumference of the flanges during and after tightening.

Features :

- Unlike bolted flanges, V Band clamps are simple & easy to mount and saves assembly time.

- Use of sheet metal for almost all components makes the assy lighter in weight

- Jupiter V band clamps are vibration proof due to their virtue of light weight and are ideal for joint to conduct output gases from vibrating assemblies at one end towards the stationary output system at the other.

- Frequent latching and unlatching of clamps for inspection, cleaning and replacement is easier.

- Corrosion resistant Stainless Steel material is used for all components as most of these joints are contaminated to hot water / salt water or hazardous chemical atmosphere.

“Each clamp manufactured at Jupiter is tested for Torque and it withstands values far above those specified by international standards”